Standard products

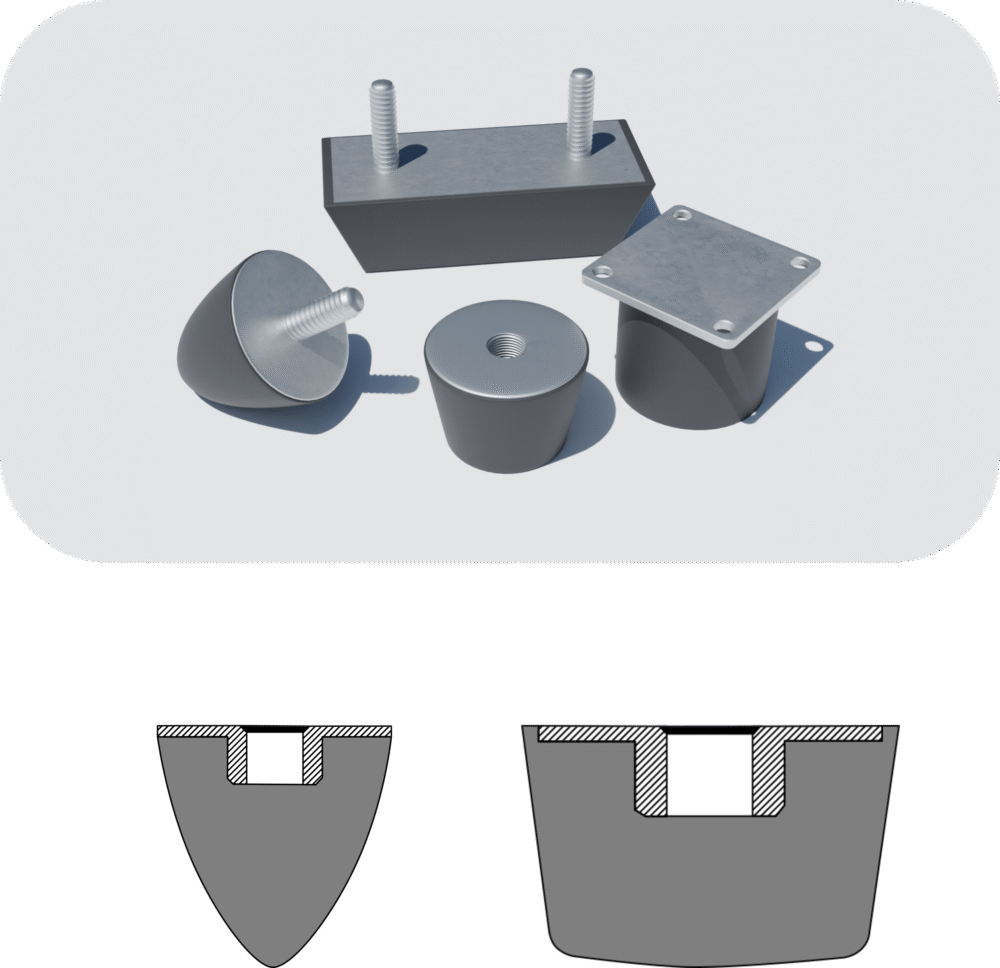

Buffers

Impact absorbers are rubber/metal parts designed to absorb the impact, shock and kinetic energy of mechanical impacts. They work mainly in direction of compression, where the rubber compound and hardness (e.g. Shore A) can be customised to achieve the right stiffness and damping capacity. Proper sizing reduces both noise and mechanical stress during stops, protecting components and structures from damage.

They are used in many different applications, such as machines, transport equipment, hatches, protective covers and other structures where movements need to be slowed down or limited.

Available in several dimensions with different thread designs. The right choice of shock absorber contributes to higher operational reliability, reduced service costs and longer service life of the machine and attachment.

Advantages of rubber impact absorbers

Impact absorbers (rubber/metal) are designed to absorb impact and shock forces, thereby protecting both machine and attachment. Due to their progressive spring characteristic, movements are softly braked and peak forces are reduced, thus extending equipment life and reducing noise levels. Typical applications include stop and end position damping in machinery, conveyors, hatches, hoods, doors and other structures where hard impacts would otherwise cause damage or noise.

High energy absorption & shock absorption

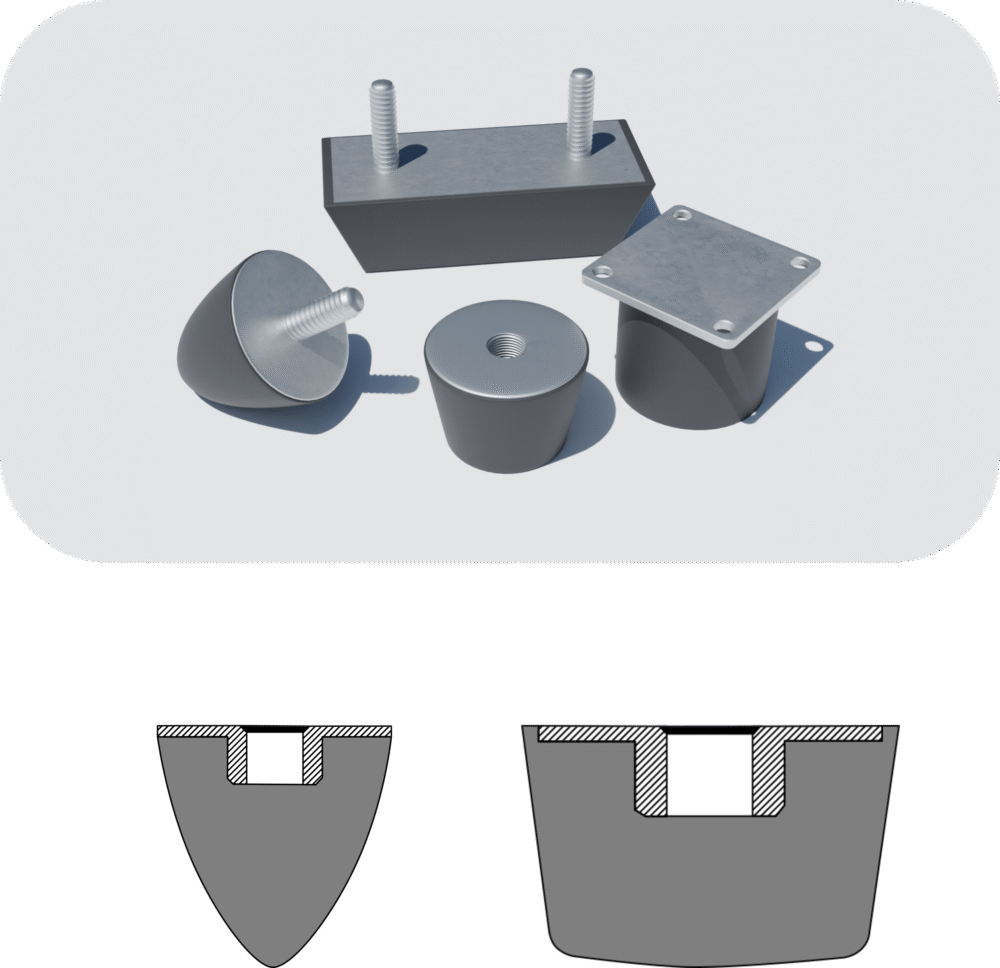

The compression-acting geometry provides controlled deflection on impact. Energy is absorbed and distributed in the rubber compound, reducing peak forces, vibrations and structure-borne noise.

Robust construction

Vulcanised rubber-metal bond provides long service life even with repeated impacts. The design can withstand high impact forces and is available with different thread types for easy assembly.

Persistent damping properties

Low permanent deformation (compression set) and good ageing resistance allow the damper to retain its function over a long time, reducing the need for maintenance and replacement.

Improving the working environment

Reducing noise and harsh impacts creates a quieter, safer and gentler working environment around machinery and equipment.

Tips for dimensioning:

Select the damper so that it can work within its optimal deformation range at impact. Adapt the hardness and size to the energy to be absorbed to achieve soft stopping and long life.