Standard products

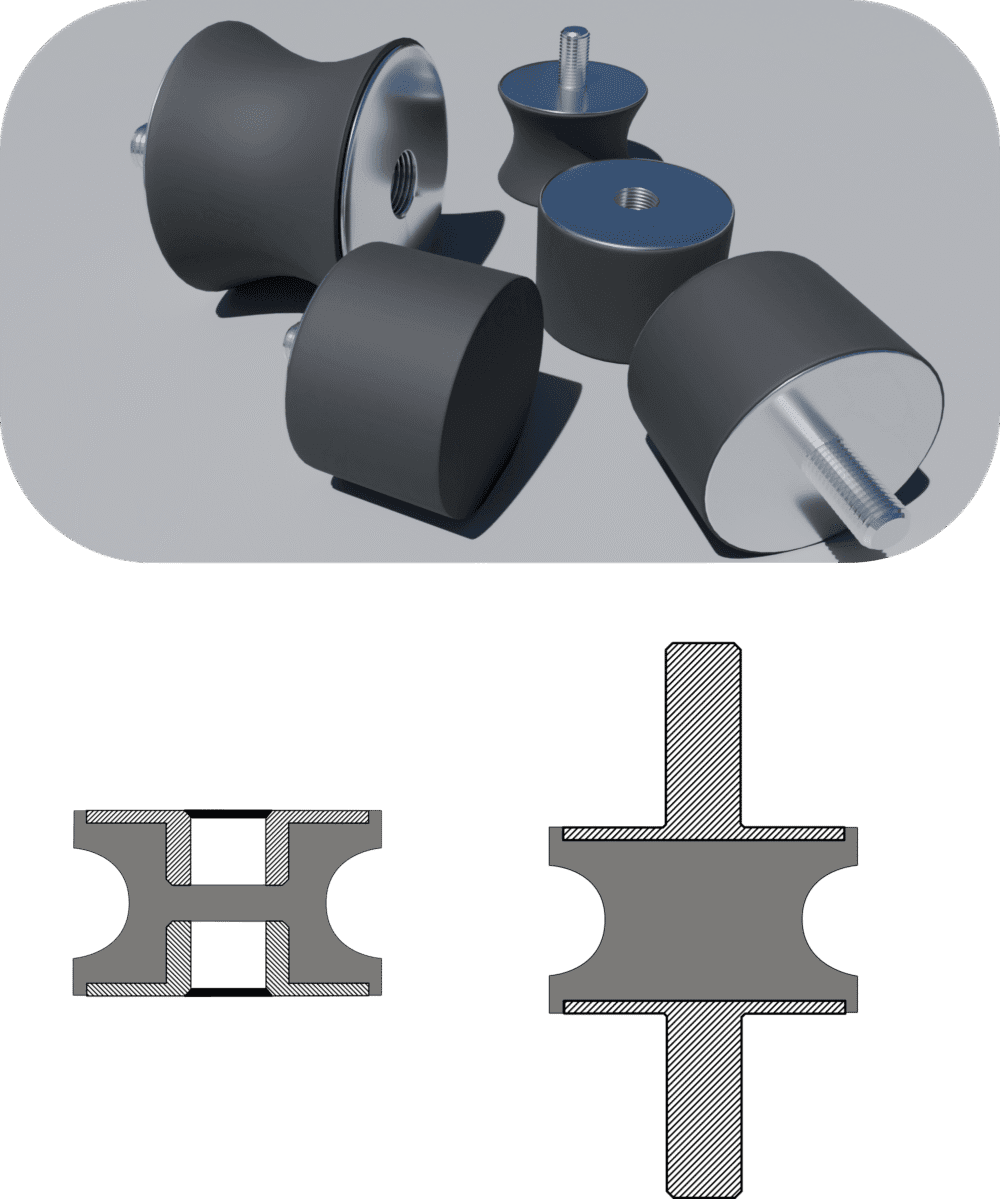

Cylindrical Vibration Dampers

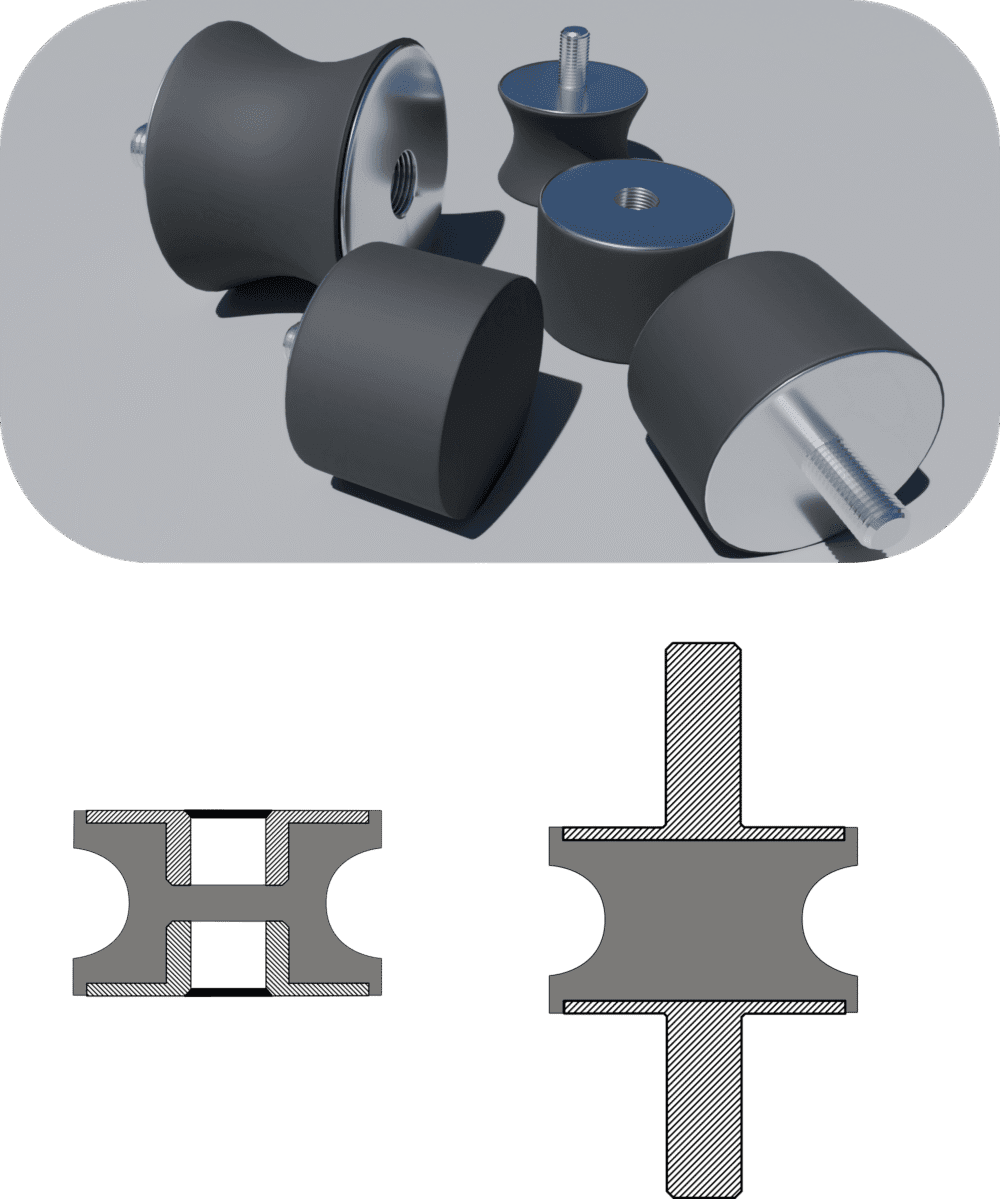

Cylindrical vibration dampers are rubber/metal components designed to reduce vibration and absorb shock forces in both axial and radial directions. By adjusting the geometry and rubber compound (e.g. Shore hardness), the natural frequency and damping ratio can be optimised to the actual operation. They are used to protect and stabilise equipment such as generators, compressors, fans, pumps and other machinery, and also act as effective machine mounts, reducing structure-borne noise and vibrations to the environment.

Available in many dimensions with internal/external thread. The right choice of damper improves operational reliability and extends the life of both machine and attachment.

Advantages of cylindrical rubber vibration dampers

Cylindrical dampers (rubber/metal) have a progressive spring characteristics which effectively absorbs and distributes shock and vibration forces in both axial and radial direction. It protects equipment and extends the life of fixings and machine components. Typical applications are machine feet and suspensions on e.g. trolleys, cabinets, doors, fans, pumps, cranes and lifting equipment.

High energy absorption & stability

The cylindrical geometry provides controlled deflection and damping under shock loads, reducing peak forces and structure-borne noise.

Robust construction

Vulcanised rubber-metal bond and durable compounds provide long service in demanding environments. Available with internal/external thread.

Persistent damping properties

Low permanent deformation (compression set) and good ageing resistance provide stable performance over time and reduce the need for frequent replacements.

Improving the working environment

Reduced vibration and structure-borne noise means quieter, more stable operation and increased safety around machinery and equipment.

Tips for dimensioning: Aim for ~10-25 % static deflection in operation and select the attenuator so that the natural frequency is well below the lowest exciting frequency. This maximises the degree of isolation and service life.