Case study

HVAC, refrigeration unit with lack of space

One manufacturer of refrigeration units had a problem with hoses and hose couplings taking up all the space in the equipment box. There was no room for other equipment and it would be almost impossible to service the equipment, while at the same time being limited in the size of the equipment box.

Challenge

The customer used standard hoses and standard couplings from recognised manufacturers. The hoses were very stiff and therefore had a large bending radius, which partly contributed to the problem.

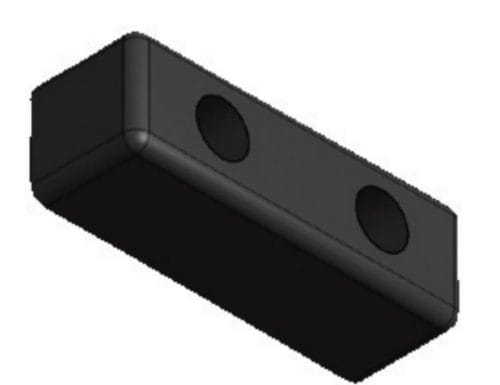

The challenge was to design a product that takes up as little space in the equipment box as possible, while replacing hoses, couplings and reducers. Of course, the hose must also be able to handle the intended media, temperatures and other requirements.

Our proposal

Our design assumed that the hose would:

- Follow the corners and edges of the appliance box to free up space.

- Can be connected directly to the intended equipment without bending.

- Include the reductions in diameter that were necessary for the connection points.

Outcome

As the volume was low but the quality requirements high, we chose as a production method to hand-wrap the hose in silicone, this is a cost-effective method for smaller volumes even though silicone itself is more expensive than EPDM, which would also have worked in this case. The choice of silicone means that we can manufacture the hose in blue colour without additional cost so that it is clearly visible with other equipment.

Need help with hoses? Get in touch with us!

Phone number

031-748 55 40E-mail address

order@ulinco.seProduct range

Our products

To explore our range, visit our online shop or browse through our physical catalogue online here.