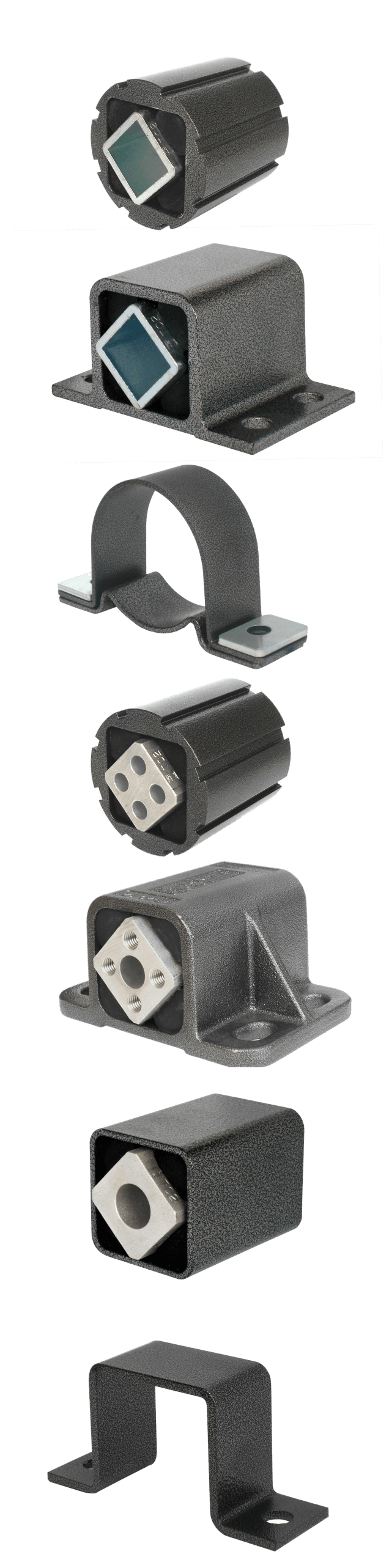

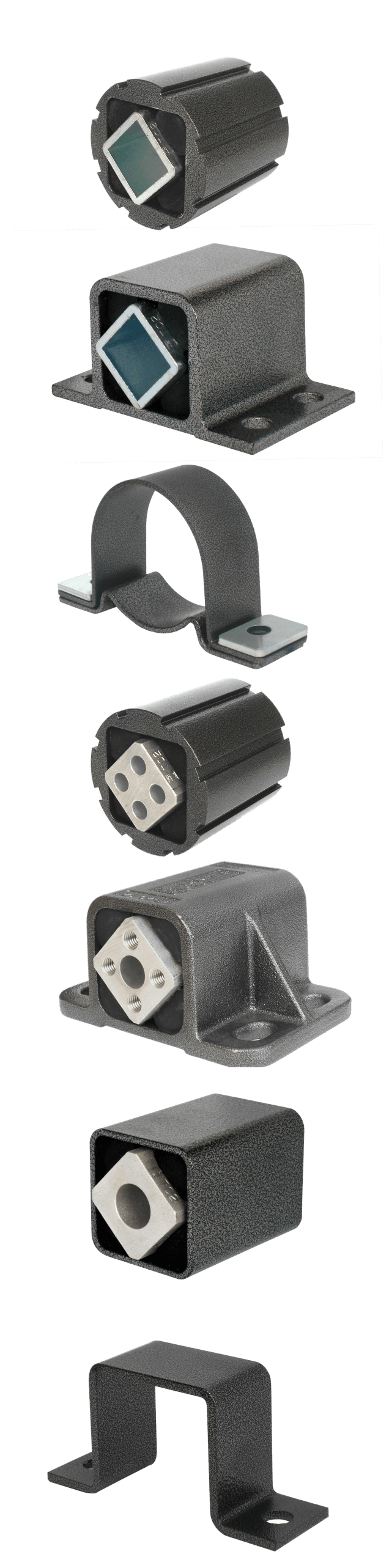

Standard products

Torsion dampers

Torsional dampers are rubber/metal components designed to absorb torque, reduce torsional vibrations and absorb shocks in rotating systems. By varying the geometry and rubber compound (e.g. Shore hardness), the torsional stiffness and damping ratio can be adjusted to optimise the dynamic characteristics of the system. They are used to protect transmissions, motors, clutches and other driveline components, helping to reduce vibration, noise and the risk of harmful resonances.

Available in different designs depending on torque range and attachment. The right choice of torsional dampers improves reliability, increases comfort and extends the life of both machine and drive system.

Advantages of rubber torsion dampers

Effective reduction of torsional vibrations

Torsional dampers (rubber/metal) are based on elastic deformation of rubber bodies that absorb torque and shocks. The design provides an elastic torsional characteristic that effectively absorbs torsional forces and protects motors, transmissions, couplings and other rotating equipment.

High energy absorption & stability

The dampers allow a maximum torsional deflection of approximately ±30° from the equilibrium position, where the torsional stiffness is inversely proportional to the oscillation frequency. This provides controlled torsion, reduces resonances and minimises peak torque and structure-borne noise.

Versatile applications

Torsion dampers can act as springs, shock absorbers, deceleration devices, oscillation supports or vibration isolation supports in a variety of applications.

Robust construction

Vulcanised rubber-metal bonding in combination with wear-resistant compounds ensures a long service life even in the event of severe torque fluctuations. The dampers are insensitive to dirt and highly resistant to water and UV radiation.

Wide temperature range

Operates in a working range between -40°C and +80°C, making them suitable for both indoor and outdoor environments in varying conditions.

Persistent damping properties

Low torsional relaxation and good ageing resistance provide stable performance over time and reduce the need for frequent replacements.

Improved reliability and comfort

Reduced torsional oscillations result in smoother running, reduced wear, and quieter and more reliable operation.

Tips for dimensioning:

Choose dampers so that the torsional stiffness and natural frequency are well below the lowest exciting frequency. This maximises the degree of isolation, reduces the risk of resonance and extends the life of both the machine and the attachment.

Wide range and advice

We offer a wide range of torsion dampers in different dimensions and designs. Please contact us if you need help choosing the right solution for your application - our engineers will guide you to the most optimal option.