Case study

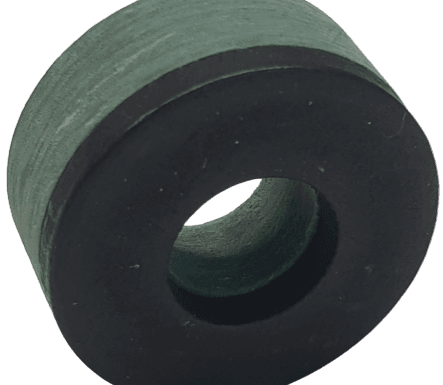

Leaking cable gland

A major heavy vehicle manufacturer had a problem with a cable gland for 10 and 18 cables leaking. On one side there was oil and oil mist with temperatures between -40°C and 135°C, and on the other side a coupling to which no oil was allowed to leak through.

Challenge

The customer used a standard CR (Chloroprene Rubber) product with significantly more holes than were used. Excess holes were sealed with plastic pins and the actual seal for the cable consisted of a knife-edge groove. Once all the cables and plastic pins were fitted, epoxy or polyurethane was moulded over the outer part to obtain a functioning sealed product.

The challenge is to design a product that seals by itself, without plastic pins and overmoulding, and in a material suitable for this application. CR (Chloroprene Rubber) is inherently not suitable for use in this temperature range.

Our proposal

Our design resulted in two different products, one for 10 cables and one for 18 cables, i.e. no plastic pins were needed to block unused holes. The geometry of the holes consisted of three "half o-rings", where the outer two had the main task of guiding the cable up so that the centre one could seal completely. In production terms, this meant tool cores that in three places had a diameter of only 0.5 mm. Through an innovative tool design, we managed to vulcanize the parts in a 64-cavity tool and get the parts out of all cavities without damaging the cores.

After initial tests and a good collaboration with the material supplier in France, we chose to manufacture the cable glands in Vamac GXF, a type of Eten-Acrylic rubber that can withstand up to 175°C, and which swells up to 5% in contact with hot oil, which improved the sealing properties. We also chose to include a friction-reducing product in the compound to facilitate installation.

Outcome

The product passed all customer specifications as well as chemical and physical tests. After 6 months of field testing in Australia, the product went into production and became a standard product on all customer engines. The ease of assembly and the fact that it didn't need to be over-moulded to seal, saved many minutes of additional labour per component and is therefore worth millions of dollars per year in total.

Do you have a problem with leakage? Get in touch with us!

Phone number

031-748 55 40E-mail address

order@ulinco.seProduct range

Our products

To explore our range, visit our online shop or browse through our physical catalogue online here.