Standard products

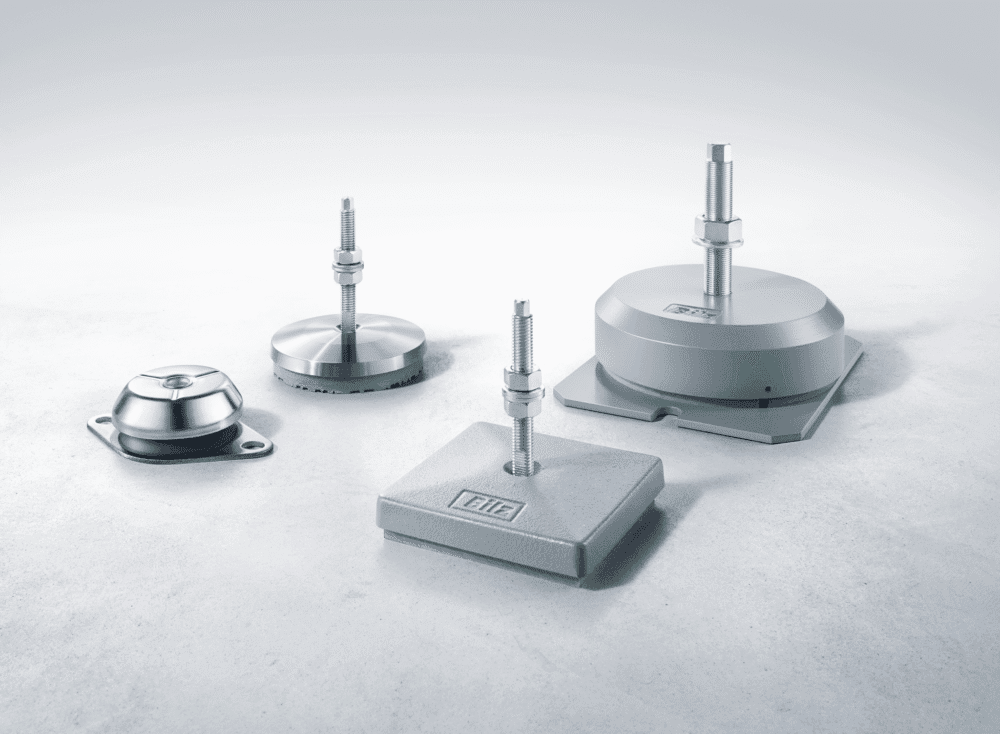

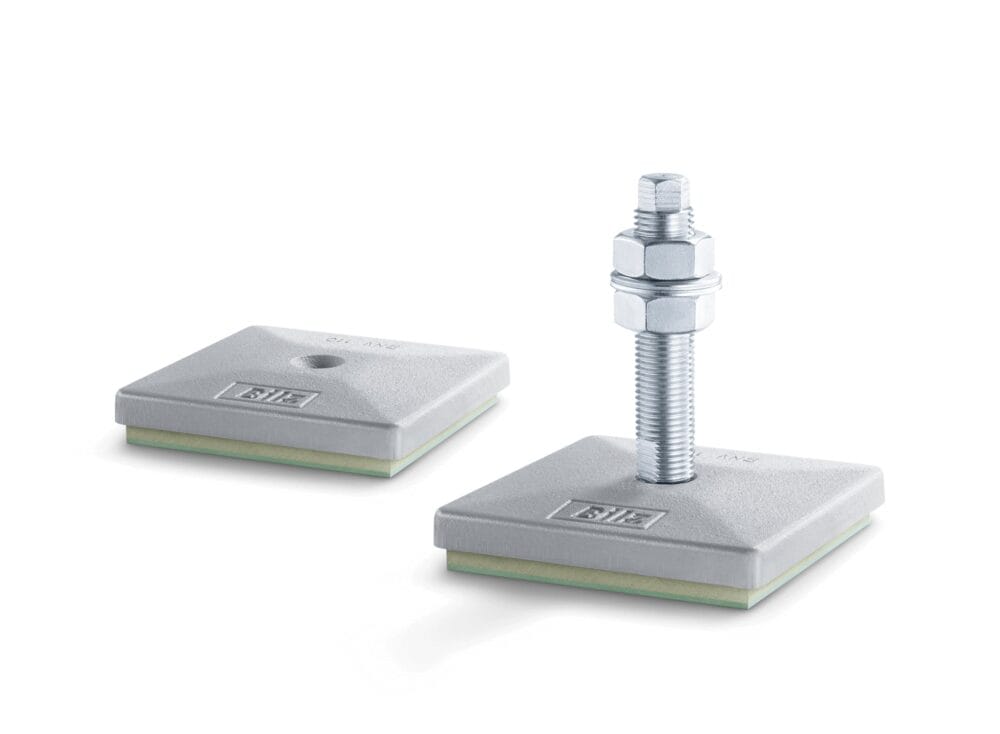

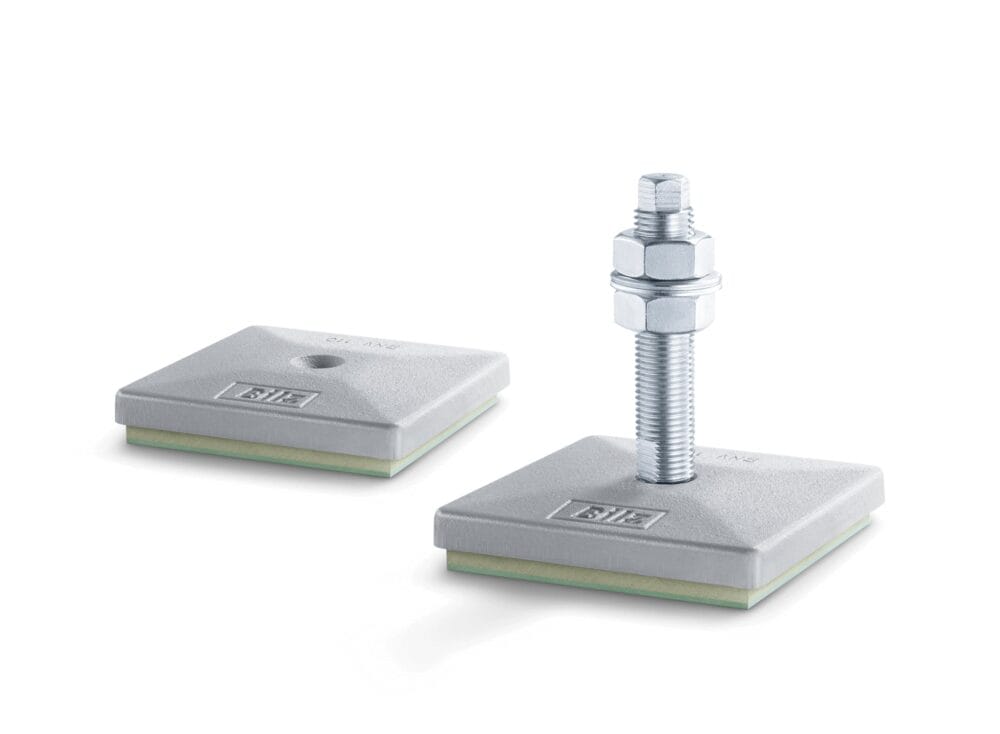

BILZ machine feet

Machine feet are maintenance-free components for vibration-isolated machine installation. As a premium variant, Bilz machine feet combine high load capacity and precise level adjustment with effective isolation against disturbing vibrations and structure-borne noise. The design ensures stability, long service life and maintained precision even under demanding operating conditions.

Bilz machine feet are used for vibration and structure-borne noise isolated machine installation. The maintenance-free machine feet enable easy and precise levelling of machines and are available in many designs. The right size and isolation plates are selected based on the application and load. The levelling range can be adjusted according to the selected bolt length and individual requirements.

- The type of insulation board is indicated in the type designation, e.g. BNSH 80/50 is equipped with insulation board B50, BNVS 50/30W is equipped with B30W, etc.

- Optimum insulation effect is achieved at about 80-90 % of the specified maximum load.

- Permissible temperature range: -20 °C to +80 °C.

Please contact us if you can't find the right dimension, colour, insulation board or bolt design for your application. In addition to our standard range and standard colours, we also offer many special solutions. Our technicians will be happy to help you choose the right solution for your needs.

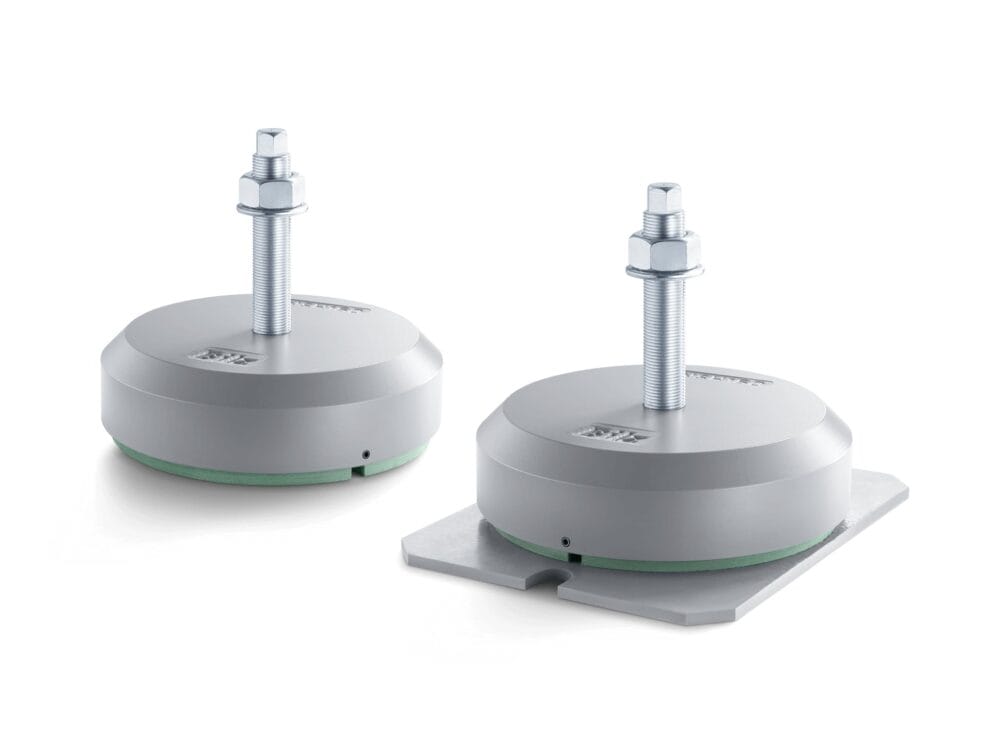

BNSH / BNSHA - For horizontal stability

Optimal horizontal stability for heavy machinery such as injection moulders, presses and punches

- Precise contact: Compatible with machines that "wander" easily

- Pressure plate design provides even load distribution

- BNSHA variant includes floor anchorage (not rollover protection)

Technical overview (selection):

- Load: 2 400 - 90 000 N per unit

- Threads: M10-M30

- Diameter: Ø80-270 mm

- Adjustment range: +6 to +18 mm

BNV / BNVS - Square levelling elements

For light to medium duty machines with threaded holes

- Compensates up to ±3° in tilt

- BNVS: fixed connection between machine and element

- Three insulating plates: B4 (universal), B0 (accurate alignment), B30W (extra damping)

Technical overview (selection):

- Load: 950 - 74 000 N per unit

- Dimensions: 60×60 to 264×165 mm

- Height: 22-47 mm

BNR / BNRS - Round levelling elements

For machines with round footplate or round attachments

- Same damping plates as BNV/BNVS

- BNRS: rigid machine connection

- Threaded bolt allows ±3° tilt compensation

Technical overview (selection):

- Load: 700 - 62 000 N per unit

- Diameter: Ø60-213 mm

- Height: 21-45 mm

BNRV / BNRSV - Stainless steel round levelling elements

Designed for cleanrooms and hygienic environments

- For the food, pharmaceutical and packaging industries

- Stainless steel design, vibration damping or anti-slip

- ±3° tilt compensation

Technical overview (selection):

- Load: 700 - 27 500 N per unit

- Diameter: Ø54-156 mm

- Height: 16-32.5 mm

BFE - Stainless and cost-effective

Affordable elements for hygiene zones with tilt compensation up to ±7.5°

- Cannot be used with Bilz insulation boards

- Withstands commercial chemicals

Technical overview (selection):

- Load: 3 000 - 30 000 N per unit

- Diameter: Ø50-125 mm

- Height: 14-19 mm

GMA - Robust vibration isolation for outdoor use

Cost-effective rubber-metal element for harsh environments, both stationary and mobile

- For pumps, fans, saws, woodworking machines, ventilation systems and generators

- High resistance to weather, dirt and mechanical shocks

- Excellent for isolating both vibration and structure-borne noise

Technical overview (selection):

- Load: 2 300 - 10 000 N per unit

- Threads: M10-M16

- Diameter: Ø83-150 mm

- Max spring travel: 3.5-5 mm ± 1.5

BNL - For highly dynamic machines

Compact and affordable solution with good vibration damping for high vertical and horizontal forces

- Resistant to lubricants, acids and alkalis

- Not compatible with Bilz insulation boards

Technical overview (selection):

- Load: 5 000 - 40 000 N per unit

- Diameter: Ø80-200 mm

- Thread: M12-M20

- Adjustment range: +12 to +20 mm